"CAG" is Edmunds Gages' acronym for Computer Aided Gaging. Synonymous with CAD (Computer Aided Drafting) and CAM (Computer Aided Manufacturing), Edmunds Gages CAG product line combines measurement signal conditioning, results displays, data gathering, and data storage in one, all-inclusive unit. Users do not require separate column amplifiers or data collectors, and there are no PC-based system problems such as incompatibilities with peripheral hardware and software programs. Our CAG product is suitable for any multi-dimensional measurement applications using manual, semi-automatic and fully automatic gages -- even closed-loop feedback systems for machine tool compensation.

Computer-Aided Gaging

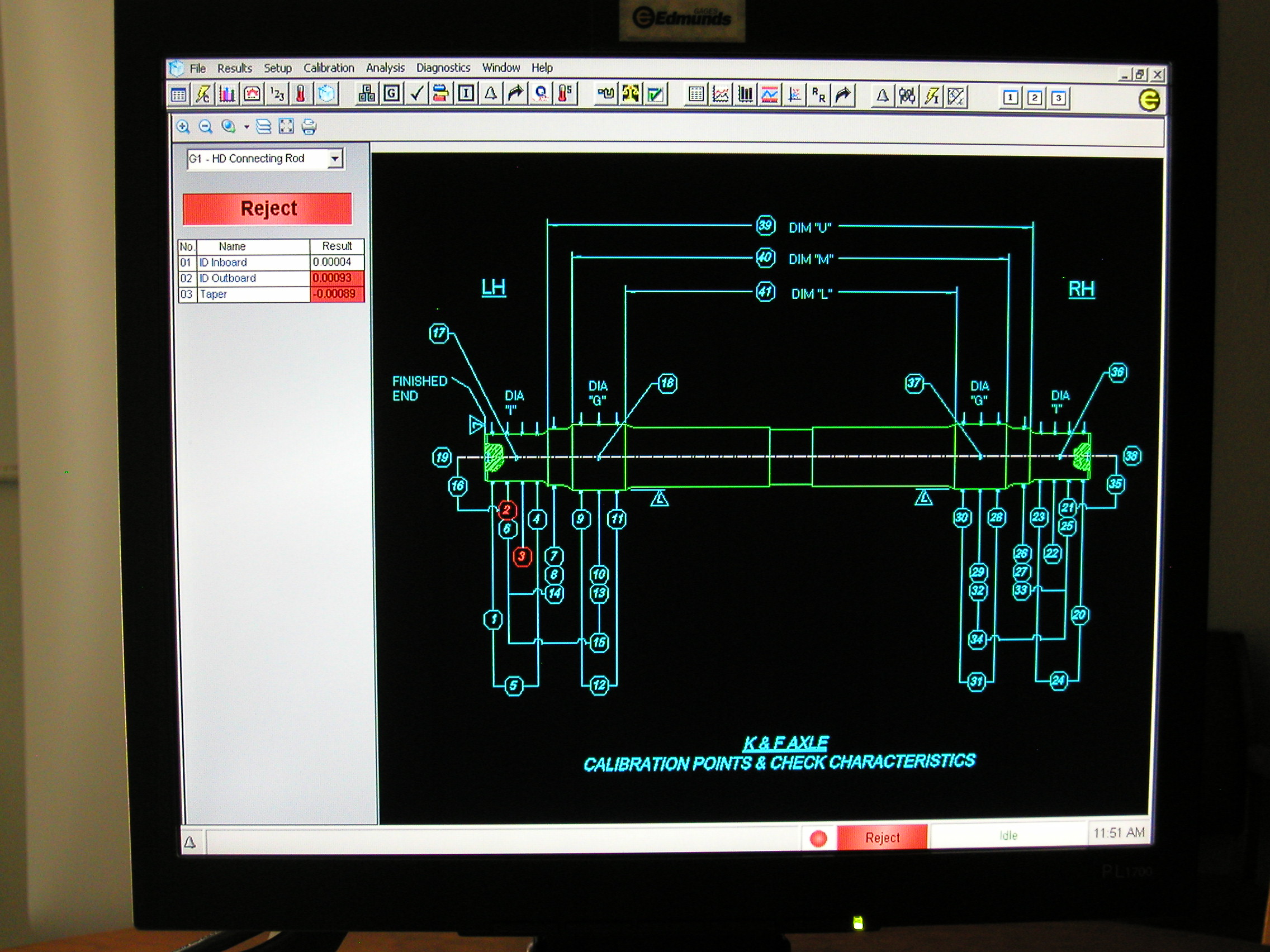

The EPIC-CAG is the top of the line for features and capability This compact 11" high x 16" wide x 9" deep unit is available with Normal remote monitor or with a built-in color Touch screen. Its cabinet is NEMA-rated for shop floor use. For even greater durability, Edmunds uses a "flash" plug-in memory card to drive the program and store the collected data instead of conventional rotating disk drives which can be unreliable in manufacturing environments. The EPIC-CAG can house up to 32 inputs, and a separate, stackable unit of the same small size expands the input capacity to 64 inputs or more. The EPIC-CAG can be tailored with customer software to fulfill your specific measurement requirements including size compensation to machine tools. The universal 4-channel signal conditioning board can accommodate Edmunds' LVDTs and air-to-electronic inputs with full range choices.

To request complete specifications and pricing information on Edmunds Gages Computer Aided Gaging, Contact us.

See Also:

EPIC-ADAMM displays measurement data -- in real time -- in a variety of numerical and graphical formats from 4 or 8 total inputs. This economical entry in the Edmunds CAG products provides results such as X-bar and R charts, bar graphs, histograms, scatter charts, and more. Detailed statistical process control information can be gleaned about part conformance, including range, mean, and deviation from nominal. Its programming and operational software is Windows like with pull down menus prompting users step-by-step through the procedures. Setup data may be stored for many part programs and password protected, if desired, to avoid inadvertent changes. Measurement results may be downloaded to a PC network via an Ethernet port.

A New Dimension In Precision Measurement

.

(860) 677-2813

Toll Free 877-521-5818