Automatic Connecting Rod Assembly Gage

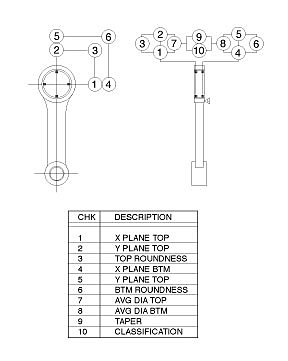

Gaging Parameters

GAGING SYSTEM: Air-to-electronic

OPERATION: Automatic

NUMBER OF CHECKS: 10

READOUT: MicroCAGTM

CLASSIFICATION: Size

FEATURES: Automatic measuring, laser engraving, and sorting into two sizes based on crank bore sizes.

The Challenge

A common dilemma in assembly operations is matching mating parts when there are incremental sizes from which to choose. A case in point is Harley-Davidson. The motorcycle manufacturer often had trouble matching the correct size cranks, bearings and connecting rods for its engines. The company needed to be able to sort the rods into two different sizes so that operators could assemble the correct crank bearing into each rod for proper fit.

The Solution

Edmunds Gages developed an automatic gage consisting of a free-standing gage base, machine control cabinet, air gaging fixtures, robotic pick and place mechanism, and our MicroCAGTM microprocessor r

In operation, an operator manually loads a rod and initiates the gaging cycle. The gaging fixture is comprised of a four-station rotary table with interchangeable part nests and air gage tooling. The connecting rod crank bore is measured in four places to acquire ten measurements. A good part within tolerance is categorized by the minimum size witnessed during measurement.

The MicroCAGTM then directs the part, based on that size, to another station in the gage where the part is laser marked with a two-digit code so that assemblers can readily view which mating part goes with it. Simultaneously, the gage also has the capability to engrave the date and the company logo.

Once the part is measured and laser marked, it is picked up by the robot and placed into one of two conveyors, classified by size, and transported to separate areas in the assembly department. Parts detected out of tolerance after initial measurement are returned to the operator for visual assessment and distribution.

The Result

The gage cycle time is 15 seconds per part, laser marking included, which is a great time and cost savings over manual gaging, considering a total of 10 measurements are taken. Further, there are no misassembled bearings on the final engine test stand. Harley-Davidson now enjoys an infallible assembly process. Since the gage has been installed, there have been zero connecting rod assembly mistakes.

A New Dimension In Precision Measurement

.

(860) 677-2813

Toll Free 877-521-5818