While the quality of cylindrical ring can vary depending on the manufacturer, customers often treat these gages as commodity items. As a result, the primary question that customers ask is, "What is your price and delivery?" In reality, that should be the last question asked. Here are several questions you should pose first, to ensure that the gages you purchase truly meet your company's requirements and industry standards.

Ten questions to ask when buying ring gages

To determine whether the ring gages you're considering will best meet your requirements, you need to ask the right questions.

What material is used to manufacture the ring gages?

It is important that the ring-gage material be stable and hard. Good-quality tool steels such as 8620 or O6 are appropriate choices. Steel blanks should be heat treated to a minimum of 62 Rc.

Do you inspect incoming material for adherence to hardening specifications?

The material is the foundation of ring-gage quality, so the answer should be an emphatic "yes."

After heat treating, do you stabilize the material?

While heat treating helps stabilize steel blanks, subsequent grinding operations can affect the material by introducing heat and stress. A quality-conscious gage manufacturer will eliminate material fluctuations entirely by putting blanks through a stabilization process, which involves cycling the rings through temperature extremes from -130 F to 300 F. Further, flange-type rings should be stabilized again after grinding.

Are your gages precision lapped by hand?

Lapping is the process in which minute amounts of material are removed to bring the ring to final size and within tolerances. It is the final process in ring manufacturing, and extremely critical. It requires a highly skilled person who has learned to "feel" a millionth of an inch. No automatic lapping machine comes as close in accuracy and precision as a person who has mastered the art. Unskilled lapping can result in rings with excessive out-of-round or tapered conditions.

Do you inspect your gages in a temperature-controlled metrology laboratory?

Although rings are inspected for size and class in a temperature-controlled lapping room, it is important that final inspection occur in a separate, environmentally controlled metrology laboratory. In addition, the master set of gages used in the lab should be traceable to the National Institute of Standards and Technology (NIST), Gaithersburg, MD.

What is the sampling of the gages you inspect?

To ensure the utmost integrity, every ring should be inspected before it is shipped to the customer.

Will you certify my ring gages?

This is becoming more important as International Organization for Standardization (IS 0), Geneva, Switzerland, and other quality-improvement programs demand gage calibration and tracking documentation. Make sure your ring-gage manufacturer has documentation systems in place to certify, track, store, and update gage information.

Do you certify both class and size?

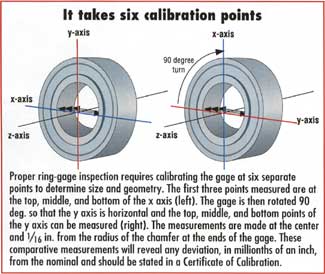

Both types of certifications detail the standards followed and include NIST-traceability statements for the laboratory. A Certification of Class simply states that the ring has been inspected and found to be within the tolerance band of the class that is marked on the ring. A Certification of Size provides actual size deviations from nominal for calibration points in two axes and three planes for each axis, for a total of six readings.

Does the certification contain a Statement of Uncertainty?

A properly prepared certification should also contain a Statement of Uncertainty for the readings given.

What is your price and delivery?

Only at this point, when you've received answers to the previous nine questions, is it an appropriate time to ask this final question.

A New Dimension In Precision Measurement

.

(860) 677-2813

Toll Free 877-521-5818